PRACLAY Gallery & Crossing test (2007)

|

|

|

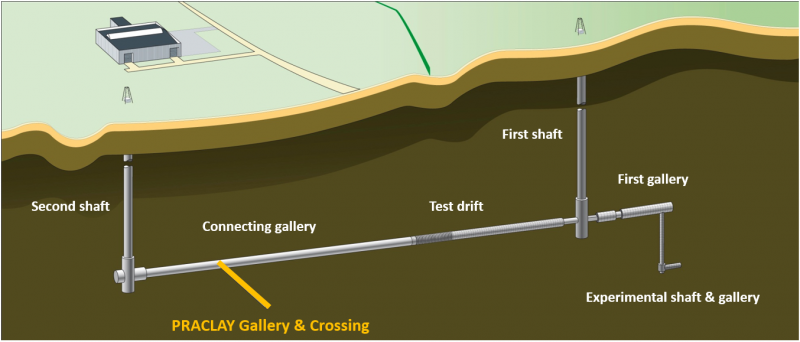

The construction of the HADES laboratory is important in order to be able to study and demonstrate the technical feasibility of geological disposal in poorly indurated clay formations like the Boom Clay. With the construction of the Connecting gallery (2001-2002), the feasibility of excavating galleries using industrial tunnelling techniques was demonstrated.

The current design by ONDRAF/NIRAS of the repository for geological disposal of category B & C waste contains disposal galleries that are perpendicular to a central gallery. Where disposal galleries connect to a central gallery, gallery crossings need to be constructed. The construction of these crossings in a plastic clay host rock at great depth (more than 200 m) poses a specific technological challenge and its feasibility needs to be demonstrated. The construction of the PRACLAY gallery and its crossing with the already existing Connecting gallery constitutes the Gallery & Crossing test.

OBJECTIVES

- Demonstrate the feasibility of constructing a crossing between two galleries without using a mounting chamber for the assembly of the tunnelling machine. Such a chamber creates significant mechanical disturbances in the host formation and is more expensive;

- Demonstrate the possibility of restarting the excavation process after an interruption by means of a stop-and-go test;

- Study the hydro-mechanical (HM) interaction between the lining and the Boom Clay.

During work on the PRACLAY gallery, it was possible to optimise the industrial excavation technique and further investigate the hydro-mechanical (HM) response of the Boom Clay to the excavation work.

The PRACLAY gallery is designed to host the Heater test, to study the impact of heat on the THM behaviour of the Boom Clay on a scale that is representative of an actual waste repository, and the Seal test, to provide the hydraulic boundary conditions for the Heater test and to explore the possibility of closing off galleries. Together, these three tests make up the PRACLAY In-Situ Experiment.

OUTCOME

With the construction of the PRACLAY gallery, the feasibility of constructing gallery crossings was demonstrated and the design proved to be adequate. The stop-and-go test was performed successfully. Several measurements (at the crossing, in the clay and in the lining) were carried out before, during and after the excavation of the PRACLAY gallery, to gain as much information as possible about the performance of the excavation technique, the behaviour of the Boom Clay and the impact of excavation on the clay. The results were in line with previous observations and confirm the highly coupled and anisotropic hydro-mechanical behaviour of the Boom Clay and known fracturing processes.

SUMMARY (.pdf)

REFERENCE PUBLICATIONS

Van Marcke P., Li X., Bastiaens W., Verstricht J., Chen G., Leysen J., Rypens J. The design and installation of the PRACLAY In-Situ Experiment. EURIDICE Report 13-129, Mol, Belgium, 2013, 190pp.

Bastiaens W., Van Cotthem A., Voorspoels T., Design and realisation of the PRACLAY experimental gallery. Building underground for the future, Monaco, 6-8 October 2008 / Association Française des Tunnels et de l'Espace Souterrain (AFTES), Limonest, France, AFTES, 2008, pp. 223-230.