PRACLAY Seal test (2010 - )

|

|

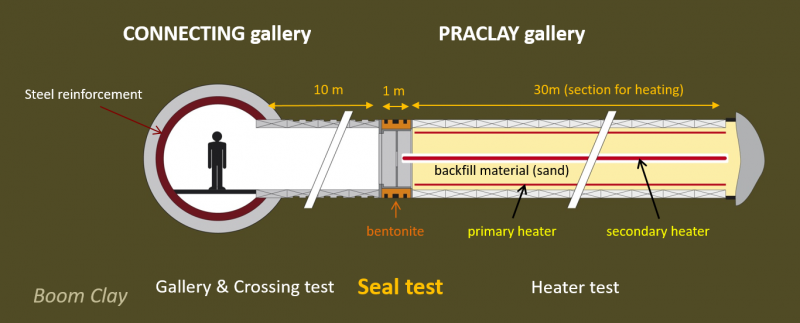

High-level radioactive waste gives off heat. When this kind of waste is eventually placed in a disposal gallery after an on-surface cooling period of 60 years, this heat will have an impact on the properties of the clay host rock surrounding the disposal gallery. The thermal impact on the clay has already been studied in a number of small-scale heating experiments. In 2007, the 45-metre long PRACLAY gallery was constructed – the so-called PRACLAY Gallery & Crossing test – to host the large-scale PRACLAY Heater test. The goal of this test is to study the impact of heat on the THM behaviour of the Boom Clay in conditions that are representative of an actual waste repository and to confirm and refine existing knowledge gained from the small-scale heating experiments.

The PRACLAY Heater test was conceived to be conducted under a well-controlled and reasonably conservative combination of thermal, hydraulic and mechanical boundary conditions. This implies, among other requirements, quasi-undrained conditions. These conditions are achieved by introducing water-saturated backfill sand into the heated part of the gallery and installing a hydraulic seal at the intersection between the heated and the non-heated parts of the gallery. The PRACLAY Seal test is related to the design, installation and functioning of this seal. Together, the Gallery & Crossing test, the Seal test and the Heater test make up the PRACLAY In-Situ Experiment.

OBJECTIVES

The main purpose of the seal is to hydraulically cut off the heated part of the PRACLAY gallery and surrounding clay from the non-heated part of the gallery. The seal consists of a steel cylinder, surrounded by a ring of bentonite. The steel cylinder physically closes off the gallery. Bentonite was used as a sealing material because of its intrinsically low permeability (when compacted to a suitable dry density) and its swelling capacity upon hydration by Boom Clay water, which helps to seal the excavation-induced zone around the seal. In this way, an almost impermeable zone is created at the intersection between the two parts of the gallery, helping to keep the pressure high inside the heated part of the PRACLAY gallery and consequently providing the quasi-undrained hydraulic boundary conditions for the PRACLAY Heater test.

The bentonite ring of the seal was instrumented to study the thermo-hydro-mechanical (THM) behaviour of the bentonite ring, more specifically its hydration and swelling behaviour.

The hydraulic seal is purpose-built for the PRACLAY Heater test and is not representative of seals in a real repository. However, the Seal test is an opportunity for studying the possibility of closing off galleries using bentonite.

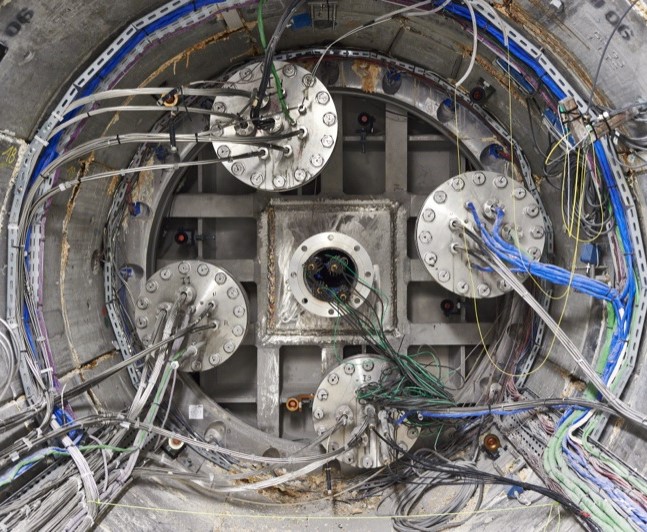

Finally, the hydraulic seal has to allow watertight feed-through of the heater cables and the instrumentation cables that are placed in the heated part of the PRACLAY gallery.

OUTCOME

The watertight steel cylinder physically closes off the gallery. Sensors installed in and around the bentonite ring show that the seal is very effective in creating the required quasi-undrained hydraulic boundary conditions and maintaining the intended high pressure conditions inside the heated part of the experiment.

SUMMARY (.pdf)

REFERENCE PUBLICATIONS

Dizier A., Chen G., Li X.L., Leysen J., Verstricht J., Troullinos I., Rypens J., The start-up phase of the PRACLAY Heater test. EURIDICE REPORT EUR_PH_16_025, Mol, Belgium, 2016, 54pp.

Van Marcke P., Li X.L., Bastiaens W., Verstricht J., Chen G., Leysen J., Rypens J., The design and installation of the PRACLAY In-Situ Experiment. EURIDICE Report 13-129, Mol, Belgium, 2013, 190pp.