Renovation SHAFT 1

In 2020 and 2021, EURIDICE has been renovating the SHAFT 1 hoisting system for the HADES underground laboratory. This renovation brought 40 years of faithful service to an end. With the arrival of the new installation, HADES' oldest access shaft has got a thorough refurbishment. The renovation was of great importance for ensuring access to this unique underground research facility in the coming decades.

EURIDICE had called in three contractors to carry out the renovation works. Swinnen NV from Balen, Spie Belgium from Geel and the German firm Thyssen Schachtbau. These contractors were responsible for the infrastructure works on the surface, the technical installations such as electricity and HVAC (Heating, Ventilation and Air Conditions) and the renovation of the hoisting system and the shaft. ONDRAF/NIRAS has financed the works. The total cost price for the works was about 7 million euros.

With the renovation of SHAFT 1 and the hoisting system, HADES and EURIDICE have started a new chapter. “In that sense, the renovation operation is at one stroke a symbol of the renewed engagement of both members, ONDRAF/NIRAS and SCK CEN, with the EIG EURIDICE and with the research into geological disposal,” says Peter De Preter, Director of EIG EURIDICE.

The renovation operation in 7 steps

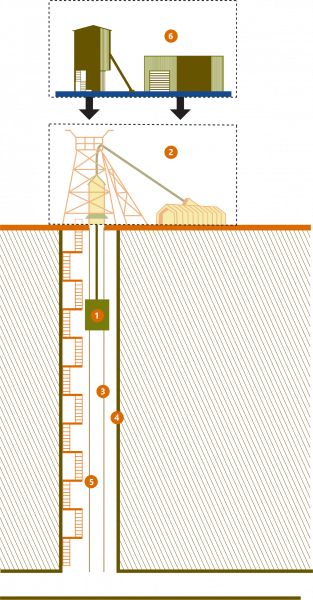

Step 1: Removing the hoisting cage and cable

First, the hoisting cage and the cable were retrieved from the shaft.

Step 2: Demolishing the tower

Next, the hoisting tower, machine room and electrical distribution centre were demolished.

Step 3: Dismantling the shaft

The caged ladder and the utility piping (including electricity, ventilation, data, water and compressed air) were removed, along with the vertical guide lanes for the hoisting cage.

Step 4: Repairing the concrete

The concrete wall was sprayed clean and repaired where necessary.

Step 5: New piping in the shaft

The contractors fitted new guide lanes for the main and emergency cage, ran electrical and data cables, fitted new compressed air and high-pressure water piping and renovated the ventilation channel.

Step 6: New hoisting building

While the works in the shaft were underway, the contractors constructed the new hoisting building. This hoisting building replaces both sheds and is kept free of frost by blowing ventilation air from the shaft into it.

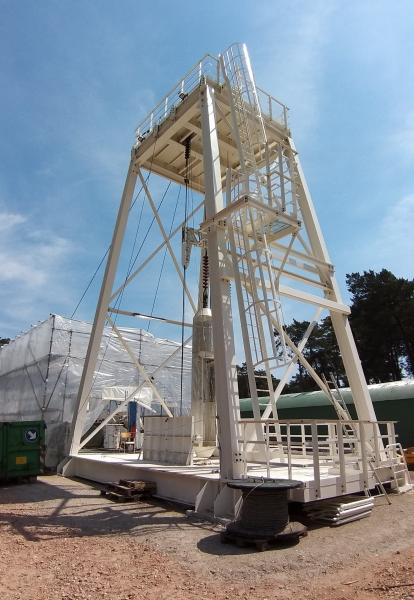

Step 7: Installing the hoisting system

Finally, the contractors installed the new hoisting system: the machine that is driving the hoisting system, the cable from which the hoisting cage hangs and the tower to carry it all.